Bed with storage drawers.

Introduction

Heaven knows there are enough woodworking plans for beds with storage drawers on the internet. And there are plenty to buy in the shops. The problem I have with the ones on sale is that there is usually a double set of drawers on each side of the bed. Even if we didn't have a pesky beam impeding any side drawer at the head of the bed on one side, we do, as do most people, have bedside tables right next to the head of the bed, which makes a drawer there uselessly impractical.

The plans that I looked at on the internet were just so solid. There was just so much wood. They were basically boxes with chest of drawers inside and a matress on top. We already have slatted bases for under our matresses. And what is a bed but a support for that slatted base? (Plus perhaps headboard which we have also eschewed because of a sloping ceiling and for space saving). And what is a drawer but a topless box hanging on runners?

It did end up costing not a huge amount less that the cheapest Ikea, say, version. Nearly half that cost was the drawer runners which cost Eur 60 ish with the recommended screws. And we did have quite a bit of wood left over. Always a compromise - I did not plan our dimensions to minimise wastage on the 122 X 244 cm sheets of wood, I planned them to maximise drawer space.

Getting going

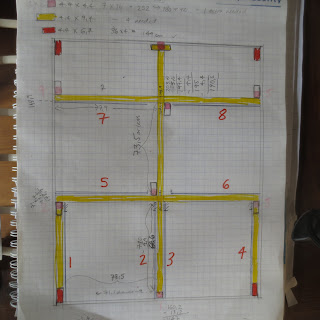

Planning planning planning to scale on blocked paper is my way to begin. The size is determined by the slatted bases, so the the inside measurement of our bed is 160cm wide, and 2m long.

I have not included exact cutting measurements - your bed might be longer or wider and your drawer requirements different.

There will be 4 drawers on our bed - two at the bottom and one each on the sides, more or less in the middle of the side. (Just beind the backs of the drawers at the bottom, in fact)

The wood I used was 18 mm thick underlayment for the sides of the bed and the sides of the drawers, and 9mm thick underlayment for the drawers fronts and bottoms, and the side panels on the bed.

For the various legs, and the central bar, I used pine beams which are 44mm X 44 or 67 or 94 mm. I used mostly what I had. I reckon 44 X 67mm would suffice for all.

For attaching the drawer runners to (apart from the drawers, natch) I used 18mm MDF (medium, supawood, depending where you're from)- beacuse it is so solid and utterly straight. It is attached at its ends to the legs which flank the drawers.

The drawer slides/runners I used were Fulterer FR1020 Drawer Slide Side Mount, width 12 mm, length 70cm. Extends 56cm when you pull drawer out. Load: dynamic up to 30 kg.

There was a bewildering selection of runners. I include this specific info not to promote these runners above others, since I have no experience of others, but because they were relatively cheap, simple, and continue to work perfectly (18 months later). They close and hold with a satisfying clunk. I think I recall that the drawers weighed about 10kg empty. So 20kg of stuff can go into them.

Don't forget to leave the required width for the runners (here 12mm each side) when you plan your sizes.

I always use torx screws (they work wonderfully well, and are absolutely ideal if you don't have the strength of an ox), and wood glue. The drawer runners recommended screws called SPAX which I ordered for the runners, and they did work perfectly fine, too.

I also used some metal corner brackets.

I decided to make the sides of the bed 20cm deep. The drawer fronts are 27cm deep. The legs overlap the sides by just 4cm at the bottom of the sides. This means that the slatted base (which is itself about 6cm deep) rests fairly deep inside the sides, and with our 20cm matress the top of the matress reaches 62cm high.

We live in an old house with sloping floors. As dismantling or removing this bed is likely to be a problem (impossibility), we decided to customise the length of each leg so that the bed sits level. Now it looks a bit skew, but it isn't! Being exactly level is necessary for the smooth running of the drawers.

So, a leg at each corner and a centre beam with a leg at each end to start with. Then legs to flank each drawer, as you can see in the photograph below.

The MDF to which the runners are attached is 15cm deep. Heed this : You need to leave about 2cm of clearance above the top of the drawer sides, so that you can lift the runners on the drawer onto the runners on the carcass. Much repositioning and cursing before I got this right.

In conclusion

I will say this : Everything worked fine until we shifted the bed from and then back into its position, then it tended not to maintain the exact squares that were necessary for the drawers to run properly.With some shoving and pulling we got it back square and running smoothly, but in the end I did put a crossbeam across the left bottom drawer to secure the squareness. It helped. This is indeed a problem that a solid sheet under the slatted bases would have avoided. I do see now why it is easier to use lots of wood, but 18 months on, all still works perfectly. Admittedly we do not move the bed now that it's on its spot. Perhaps using big metal corner brackets on the inside corners would also have helped.

The side panels, where there are no drawers or where the sides of the drawers would otherwise be visible, are, as mentioned, 9mm underlayment, like the drawer fronts. The side panels at the head of the bed are attached with magnets, so can easily be removed. I did this mostly so that our cat can get under the bed to hide when the Dutch go beserk with fireworks on New Year's eve, but it could give access for storage of very seldom needed items.

Go for it, I say!